-

What Is a Flatbed Semi-Trailer and How Does It Work? Definition and Structural Design A Flatbed Semi-Trailer is a type of transport vehicle commonly used for th...

READ MORE -

From massive construction projects to cross-country logistics, the role of reliable hauling equipment is more vital than ever. One vehicle that stands out in th...

READ MORE -

When it comes to moving large loads or transporting heavy equipment, a Heavy Duty Trailer is an indispensable tool in the transportation industry. Whether for c...

READ MORE -

What is a flatbed semi-trailer, and how does it differ from a regular trailer? A flatbed semi-trailer is a simple, open-platform vehicle. Its key feature is the...

READ MORE -

Definition and Basic Structure of a Semi-trailer: How Does It Work? In modern logistics and transportation, semi-trailers have become a staple of long-distance ...

READ MORE

What are the main types of heavy-duty trailers? What are their typical applications?

Q1: What types of heavy-duty trailers are there?

A: In the global specialty transport and bulk logistics sectors, heavy-duty trailers come in a variety of types, with designs optimized for different cargo weights, sizes, and transportation environments. They can generally be categorized into the following categories:

Hydraulic Axle Semi-Trailer

SPMT (Self-Propelled Modular Transporter)

Wind Turbine Transport Trailer

Construction Machinery Transport Trailer

Precision Instrument Transport Trailer

Tower Clamp Transport Trailer

Side-Curtain Semi-Trailer

Special-Function Trailers (such as those with variable wheelbases and powered goosenecks)

Since its establishment in 2020, Hangzhou Kotter Intelligent Manufacturing Co., Ltd., leveraging its qualifications under the "Announcement of China's Automobile Manufacturing Enterprises and Products" and its "3C" mandatory certification, not only produces the aforementioned mainstream heavy-duty trailers but also continuously develops solutions to meet customized needs.

Q2: What are the advantages and application scenarios of hydraulic axle semi-trailers?

A: Hydraulic axle semi-trailers use a hydraulic suspension system to distribute the load, maintaining vehicle stability in complex road conditions. They are particularly suitable for transporting overweight, overlong, and overwide cargo, such as large chemical equipment, generator sets, and large boilers.

Applications: Power construction, large-scale chemical projects, and port and terminal transportation.

Kotter Advantages: The company offers high-end features such as multi-axle hydraulic steering, hydro-pneumatic suspension, and a variable wheelbase, ensuring safe and efficient transport for international projects.

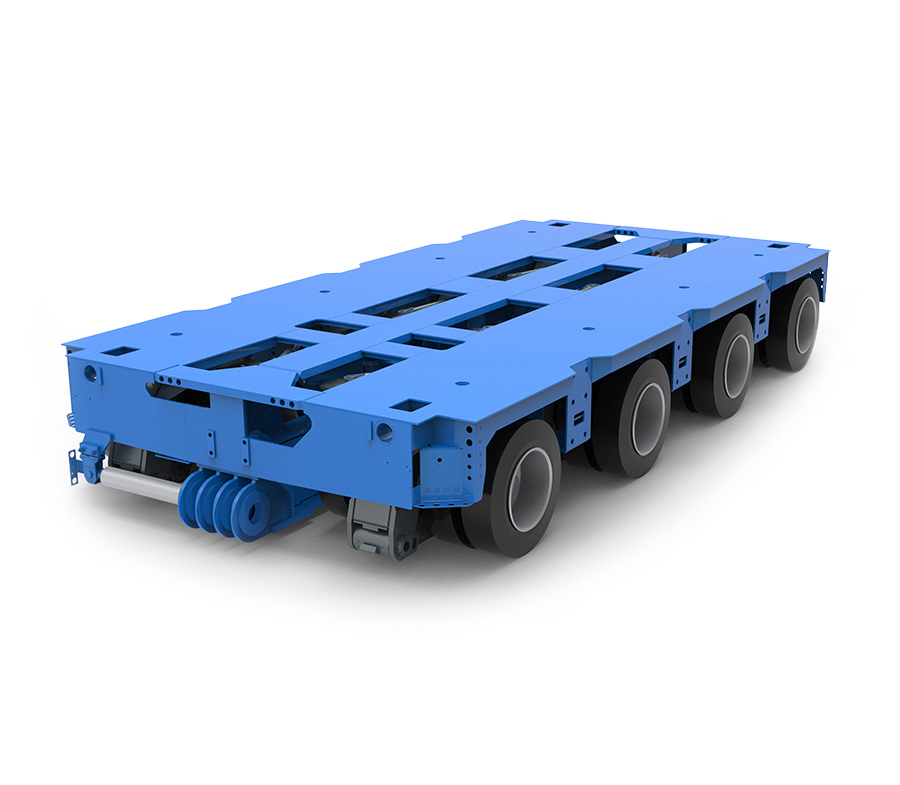

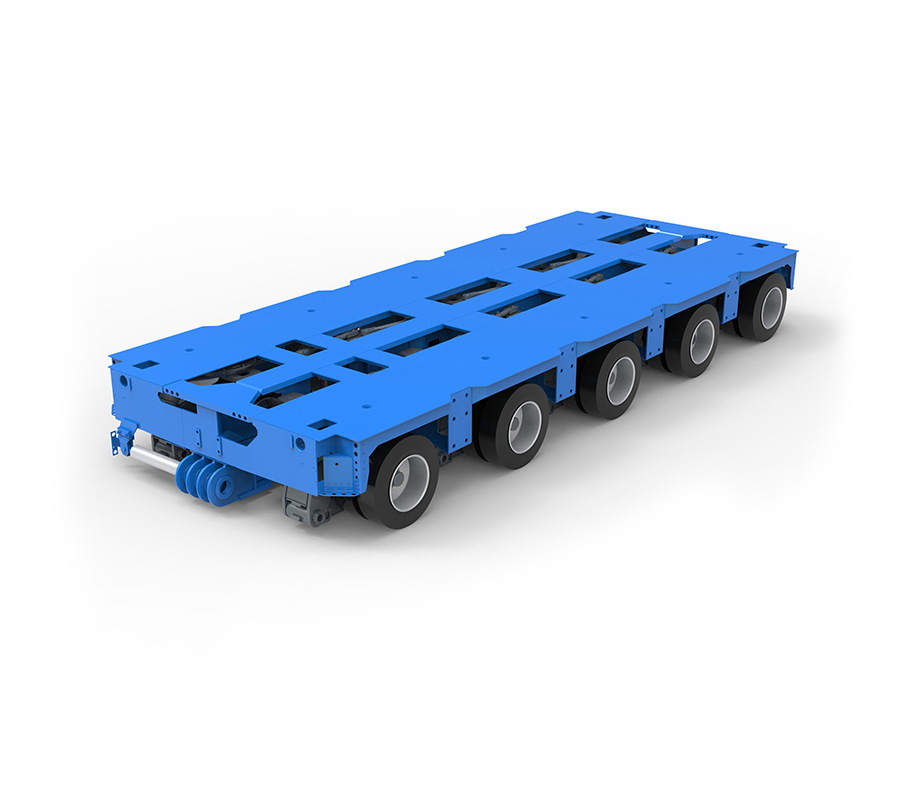

Q3: What is unique about the SPMT modular transporter?

A: The SPMT (Self-Propelled Modular Transporter) is a self-propelled modular vehicle that can achieve a load capacity of thousands or even tens of thousands of tons by combining multiple units and supports omnidirectional travel.

Applications: In-plant or short-distance transfers of ship hulls, offshore platforms, and ultra-large steel structures.

Kotter Advantages: The company's SPMT modular vehicle features a high-precision hydraulic synchronization system and flexible module connections, making it suitable for large-scale handling tasks for domestic and international general contractors.

Q4: What are the design features of the wind turbine equipment transport trailer?

A: Wind turbine blades and towers are enormous, requiring trailers with telescopic, rotating, and obstacle avoidance capabilities for transport.

Application: Wind farm construction, where blades can be transported over 80 meters.

Kotter Advantages: Kotter's wind turbine blade transport trailers can be equipped with a powered gooseneck and hydraulic lift system, enabling safe navigation through mountainous terrain and tight curves, making them highly sought after by customers in the new energy industry.

Q5: What are the main areas of demand for trailers for transporting construction machinery?

A: Construction machinery such as excavators, bulldozers, and crane chassis are typically heavy and have a high center of gravity, requiring trailers with a low loading height and high load capacity.

Applications: Infrastructure construction, mining, and port handling.

Kotter Advantages: We offer low-bed semi-trailers with high-strength steel structures and a removable gooseneck design, facilitating quick loading and unloading of large machinery.

Q6: What is the difference between a trailer for transporting precision equipment and a standard trailer?

A: Precision equipment such as medical accelerators and large experimental devices are extremely sensitive to vibration and tilt during transportation.

Applications: Equipment handling in high-end manufacturing, research institutes, and large hospitals.

Kotter Advantages: Kotter's precision transport trailers are equipped with a hydraulic balancing system and multi-point fixings, effectively reducing shock and vibration during transportation.

Q7: What is the function of a tower clamp transport trailer?

A: It is used to vertically clamp wind turbine towers, reducing the transport footprint and enabling flexible maneuvering on mountain roads.

Applications: Mountain wind farm construction.

Kotter Advantages: Kotter's tower clamp trailers feature hydraulic clamping, automatic centering, and tilt compensation, significantly improving transportation efficiency.

Q8: Why are curtain-side semi-trailers so popular in international logistics?

A: Curtain-side semi-trailers have fully openable sides, facilitating forklift loading and unloading of large items or pallets. They also offer excellent waterproof and dustproof properties. Application Scenarios: Cross-border transportation, retail distribution, and warehousing and logistics.

Kotter Advantages: Our aluminum alloy curtain-side semi-trailers are significantly lightweight, effectively reducing fuel consumption and increasing legal cargo capacity.

Q9: When are special-purpose trailers used?

A: When transporting over extremely long distances, in challenging terrain, or when cargo requires repositioning during transport, trailers with special features such as variable wheelbases, powered goosenecks, and hydraulic suspension are used.

Application Scenarios: Cross-border special transport, offshore wind power projects, and bridge transport.

Kotter Advantages: We can customize a variety of special-function combinations based on customer project requirements, providing end-to-end engineering transportation solutions.

Q10: Why choose Hangzhou Kotter Intelligent Manufacturing Co., Ltd.?

A:

Qualifications: We comply with the management requirements of China's "Announcement on Automobile Manufacturing Enterprises and Products" and hold "3C" certification.

Full Product Coverage: We offer a full range of products, including hydraulic axle trailers, SPMT modular vehicles, wind power transport trailers, lowbed trailers, and precision transport trailers. Leading Technology: Mastering core technologies such as multi-axle steering, hydro-pneumatic suspension, hydraulic suspension, and powered gooseneck.

Global Service: Providing full-process support for design, manufacturing, export, and after-sales service for domestic and international customers.

Common Towing Connection Methods for Heavy-Duty Trailers

Fifth-Wheel Coupling

Principle and Features

The fifth-wheel coupling is the most common semi-trailer connection method worldwide. It utilizes a saddle mounted on the tractor and a kingpin at the front of the trailer, which interlock for a quick and secure connection.

Kingpin Diameter: Commonly 2 inches or 3.5 inches, it determines the trailer's rated towing weight.

Advantages: Stable connection, easy assembly and disassembly, suitable for standard transport.

Limitations: For extremely heavy loads or with unusual load distribution, additional stability measures may be required.

Typical Applications

International standard container transport, long-distance bulk cargo transport, and some low-bed semi-trailers. Kotter Solutions

Hangzhou Kotter offers multi-axle lowbed and curtain-side semi-trailers, often featuring high-strength alloy drawbars and reinforced saddle connection structures, ensuring safety and reliability during cross-border and long-distance transport.

Power Gooseneck Coupling

Principle and Features

The power gooseneck is a hydraulically controlled coupling structure that can be raised and lowered. It is commonly used on hydraulic axle trailers and special transport vehicles. It connects directly to the tractor's saddle and raises and lowers the cargo platform via a hydraulic system.

Advantages: It allows for rapid loading and unloading of heavy cargo and accommodates loading platforms of varying heights.

Flexibility: The front end height can be adjusted, making it suitable for complex road conditions.

Typical Applications: Hydraulic axle semi-trailers transport large construction machinery, transformers, wind turbine equipment bases, and more.

Kotter Solutions

Kotter's high-tech hydraulic axle semi-trailers are all equipped with a power gooseneck. Combined with features such as variable wheelbase and multi-axle steering, they maintain excellent maneuverability and maneuverability in mountainous terrain, tight curves, and narrow roads.

Drawbar Coupling

Principle and Features

A drawbar coupling connects a rigid or retractable drawbar at the front of the trailer to a towing hook (or eye) at the rear of the tractor. It is commonly found on full-length trailers or heavy-duty multi-axle flatbed trailers.

Advantages: Simple structure, low cost, suitable for short to medium distances and intra-factory transport.

Steering Characteristics: Typically used with front-axle steering, it offers a small turning radius.

Typical Applications: Internal transport in ports, steel mills, mines, and construction sites.

Kotter Solutions

Hangzhou Kotter's full-length tower clamp transport trailers and in-factory modular trailers can be equipped with optional high-strength drawbars and wear-resistant towing eyes, ensuring reliable connection even under heavy loads and easy maintenance.

Spherical Coupling

Principle and Features: A spherical coupling achieves full angle compensation through a single ball joint and is commonly used on light-duty and some specialty trailers. Although less common in heavy-duty trailers, they still have application value in special conditions (such as agricultural heavy-duty vehicles and special engineering trailers).

Advantages: Strong angle compensation capability and adaptability to uneven roads.

Limitations: Limited load capacity in extremely heavy-duty transport.

Typical Applications: Agricultural machinery transport and light special equipment transfer.

Kotter Solutions: The company can customize spherical coupling systems for special projects, combined with hydro-pneumatic suspension technology to improve stability on irregular road conditions.

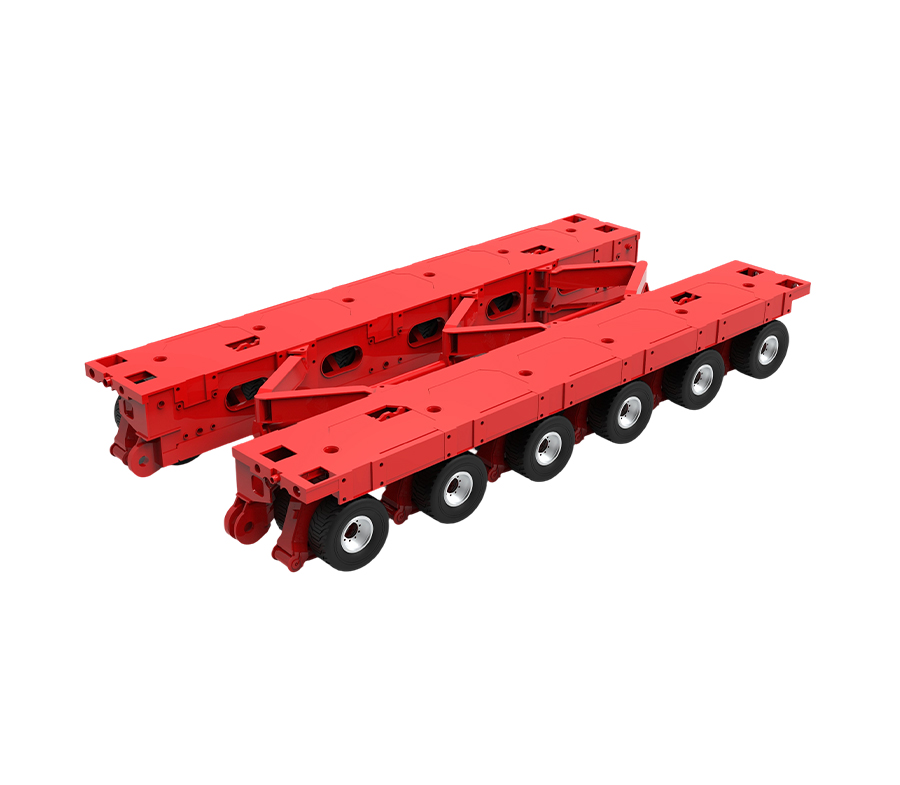

Modular Mechanical Coupling

Principles and Features: The connections between SPMT modular transporters typically utilize high-strength mechanical latches and hydraulic locking devices, which can transmit tremendous traction and maintain hydraulic synchronization among multiple modules.

Advantages: Infinitely scalable and combinable, with exceptional load capacity.

Precision Control: Combined with the hydraulic system, millimeter-level synchronized lifting and lowering are achieved.

Typical Applications: Transport of large vessels, offshore drilling platforms, chemical towers, and other oversized items. Kotter Solutions

Hangzhou Kotter's SPMT modular vehicles support a variety of coupling methods, meeting the flexible scheduling needs of domestic and international heavy-duty transport contractors.

Customized Coupling Systems

Principles and Features

Overweight transport tasks such as wind power, nuclear power, and bridge construction often require fully customized traction couplings, including rotatable coupling frames, hydraulic clamping systems, and telescopic support beams.

Advantages: Optimized load-bearing structures and transport postures tailored to cargo characteristics.

Fully Customized: Tailored to cargo weight, size, and transport routes.

Typical Applications: Transport of wind turbine blades, nuclear reactor shells, and large bridge structures.

Kotter Solutions

Leveraging mature R&D capabilities and international engineering collaboration experience, Kotter provides customers with comprehensive support from concept design and structural manufacturing to on-site commissioning.

What are the common wear and failure points of heavy-duty trailers?

Tire and Wheel Wear

Common Problems

Uneven Wear: Common in multi-axle trailers, caused by uneven tire pressure or suspension system malfunction.

Lateral Wear: Occurs when driving through frequent sharp turns or on winding roads.

Heating Wheel Bearings: Caused by insufficient lubrication or chronic overloading.

Impacts

Tire wear not only reduces driving safety but also increases fuel consumption; damaged wheel bearings can cause wheel locking or wheel fall-off.

Kotter Solutions

Kotter's multi-axle hydraulic steering and hydro-pneumatic suspension systems effectively reduce tire slip and lateral wear. They are also equipped with high-capacity bearings and an intelligent tire pressure monitoring system (TPMS), helping customers reduce maintenance costs.

Brake System Wear

Common Problems

Brake Drum (Disc) Overheating: Frequent braking on long downhill slopes or improper brake clearance adjustment.

Abnormal Brake Pad Wear: Uneven braking force distribution, resulting in excessive braking on some wheels.

Brake Air Line Leakage: Deteriorating seals or loose pipe connections.

Impacts

Degraded braking performance is a major safety hazard, especially when driving heavily loaded at high speeds or transporting heavy goods on mountain roads. Kotter Countermeasures

The company's trailers feature an Electronic Braking System (EBS), which precisely distributes braking force across all axles. High-temperature-resistant brake pads and highly sealed air circuit components extend the life of the brake system.

Suspension System Wear

Common Problems

Rubber Bushing Aging: Long-term heavy loads and adverse weather conditions accelerate aging.

Hydraulic/Airbag Suspension Leakage: Seal wear or pipe damage can lead to suspension failure.

Increased Connecting Pin Shaft Play: Impacts vehicle stability and comfort.

Impacts

Suspension system failure can directly increase tire wear, reduce ride stability, and even pose the risk of cargo overturning at high speeds.

Kotter Countermeasures

The hydro-pneumatic and hydraulic suspensions provided by Kotter utilize highly wear-resistant seals and anti-corrosion treatments to withstand extreme cold, high temperatures, and salt spray environments. Some products feature adjustable suspension height to reduce the impact of complex road conditions on the suspension.

Traction and Connecting Component Wear

Common Problems

Saddle Wear: Long-term friction between the towing pin and the saddle locking mechanism causes increased play.

Towpin Wear: Rapid wear after the hardened surface layer falls off. Loose power gooseneck connections: Wear on the hydraulic pin or lock leads to a loose connection.

Impact

Failure of the towing connection can cause the trailer to separate from the tractor, a high-risk failure.

Kotter Countermeasures

Our towing system uses high-strength alloy steel towing pins and wear-resistant coated saddle locks, and incorporates hydraulic lock monitoring into the power gooseneck structure to ensure a secure connection.

Hydraulic System and Pipeline Leaks

Common Problems

Hydraulic oil pipe burst or leakage: Caused by large pressure fluctuations or aging pipes.

Loose joints: Caused by high-frequency vibration or improper assembly.

Hydraulic oil contamination: Impurities entering the system wear out hydraulic components.

Impact

Failure of the hydraulic system can directly affect the trailer's lifting, steering, loading and unloading functions, causing transport disruptions.

Kotter Countermeasures

Kotter hydraulic systems utilize high-pressure hoses and quick-connects, and are equipped with a high-precision filtration system to ensure clean and stable system operation.

Structural Fatigue and Corrosion

Common Problems

Weld cracking: Caused by heavy load impact or poor manufacturing quality. Steel beam fatigue: Long-term heavy loads and frequent turbulence can cause fatigue cracks in the main beam.

Corrosion: Salt spray, acidic environments, or sea transportation accelerate corrosion.

Impacts

Structural failures can cause the trailer to be unable to safely carry loads or even become unstable.

Kotter Countermeasures

Kotter trailer main beams are constructed of high-strength low-alloy steel and are sandblasted and coated with a multi-layer anti-corrosion coating. Critical welds undergo dual inspections using ultrasonic testing (UT) and magnetic particle testing (MT) to ensure structural reliability.

English

English  中文简体

中文简体